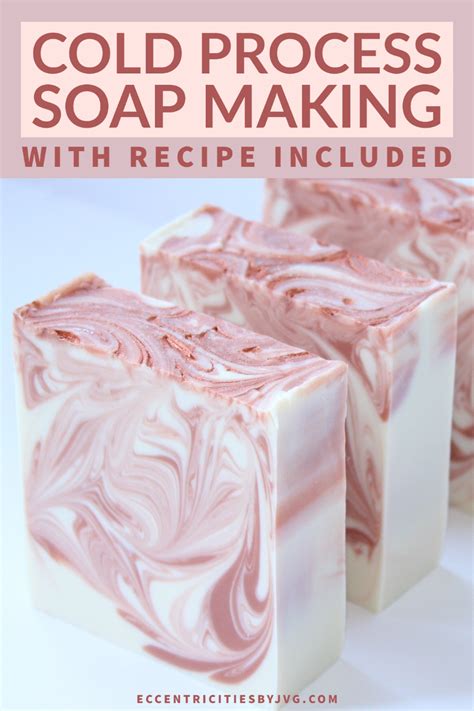

The Ultimate Guide to Cold Process Soapmaking: A Beginner's Recipe

Making your own cold process soap is a rewarding experience, allowing you to control ingredients, create unique scents, and avoid harsh chemicals found in commercial soaps. This comprehensive guide provides a beginner-friendly cold process soap recipe and essential tips for success. We'll cover everything from essential supplies to troubleshooting common issues.

Understanding the Cold Process Method

Cold process soapmaking involves a chemical reaction called saponification. This process combines oils and lye (sodium hydroxide) to create soap. The heat generated during saponification is enough to solidify the soap mixture. No external heat is needed, hence the term "cold process."

Why Cold Process?

- Customization: Control over ingredients like oils, butters, and essential oils allows for personalized soap creations.

- Natural Ingredients: Avoid harsh chemicals and preservatives often found in commercial soaps.

- Cost-Effective: Making your own soap can be more economical in the long run.

- Creative Outlet: Experiment with colors, scents, and additives to create unique and beautiful soaps.

Essential Supplies for Cold Process Soapmaking

Before you begin, gather these crucial supplies:

- Safety Gear: Gloves, eye protection, and a long-sleeved shirt are absolutely essential to protect yourself from lye.

- Scale: An accurate digital scale is crucial for precise measurements. Gram measurements are recommended for accuracy.

- Heat-Resistant Containers: Stainless steel or glass bowls are ideal for mixing.

- Thermometer: A digital thermometer ensures accurate temperature readings.

- Mould: Silicone molds are easy to use and demould. Wooden molds are also popular.

- Stick Blender: A stick blender is essential for efficiently mixing the oils and lye solution.

- Spatula: For scraping down the sides of your mixing bowl.

Basic Cold Process Soap Recipe (Beginner-Friendly)

This recipe yields approximately 1 lb of soap.

Ingredients:

- 250g Olive Oil (provides lather and conditioning)

- 100g Coconut Oil (creates hardness and lather)

- 75g Palm Oil (adds hardness and creaminess) (Consider replacing with Shea butter for a vegan option)

- 87g Lye (Sodium Hydroxide - NaOH) Handle with extreme caution!

- 200g Distilled Water

Instructions:

- Prepare the Lye Solution: Carefully add the lye to the distilled water slowly, stirring gently with a heat-resistant utensil. The mixture will get very hot. Allow it to cool. Always add lye to water, never water to lye.

- Combine the Oils: Measure your oils into a heat-resistant bowl. Melt any solid oils if necessary using a double boiler or microwave. Let the oils cool.

- Combine Lye Solution and Oils: Once both the lye solution and oils have cooled to around 100-110°F (38-43°C), slowly pour the lye solution into the oils.

- Mix with Immersion Blender: Use the immersion blender to carefully mix the lye solution and oils until the mixture reaches a "trace." Trace is when the mixture thickens and leaves a trail on the surface when you lift the blender.

- Add Additives (Optional): At trace, add any essential oils, colorants, or other additives you wish to incorporate. Remember to adjust the recipe accordingly.

- Pour into Mould: Carefully pour the mixture into your prepared mold.

- Insulation: Cover the mold with a towel or blanket to insulate it and retain heat. This helps with saponification.

- Curing: Allow the soap to cure for 4-6 weeks in a cool, dry place. This allows excess water to evaporate and the soap to harden. During this time, the saponification process is completed.

Tips for Success

- Accuracy is Key: Use a precise scale for accurate measurements. Inaccurate measurements can result in a poor-quality soap.

- Safety First: Always wear safety gear when handling lye.

- Temperature Control: Maintaining the correct temperature of both the lye solution and oils is crucial.

- Proper Mixing: Thorough mixing is essential to achieve proper saponification.

- Patience is a Virtue: Allow the soap to cure properly to ensure a long-lasting, gentle bar of soap.

Troubleshooting Common Problems

- Soap is too soft: This could be due to an insufficient amount of hard oils (coconut or palm).

- Soap is too hard: An excess of hard oils might be the cause.

- Soap is grainy: This could result from improper mixing or inadequate curing time.

By following this guide and practicing safe soapmaking techniques, you can create beautiful and functional cold process soaps. Remember to always prioritize safety and enjoy the creative process!